During the last 15 years, rifle barrels have almost completely prevailed over pressed barrels, especially in the arena of precision competitive shooting This situation led to prolonged delivery times for the manufacturers of good rifle barrels. The bottle neck motivated us to produce barrels in small series with the „Single Cut Rifling Method“ as of 2008. The well-known US bench-rest barrel manufacturers became our role models back then.

The material is supplied as bar stock (US 416R Stainless), then cut to size and stress relieved in a furnace. The blanks are then drilled on-site with our deep-hole drilling machines. After the barrel has been turned to the desired outer contour, it is once again stress-relieved in the oven to minimize any residual stresses in the material, ensuring optimal precision and durability for hunting rifles. Now the barrel is ready to be reamed to its field diameter on our CNC barrel reamer. The barrel is then pulled on the in-house developed and built CNC drawing machine. The rifling grooves are cut individually with a chip thickness of 0.002 mm, then hand-lapped and inspected with an endoscope.

Barrel changes are carried out in-house for almost all bolt-action rifles and calibers. For better understanding: We create exchangeable barrels for Blaser R93 and R8 with a locking bushing made out of original Blaser barrel steel, into which the barrel is then screwed.

We would like to thank the Blaser company for granting us the license to produce R8 barrels.

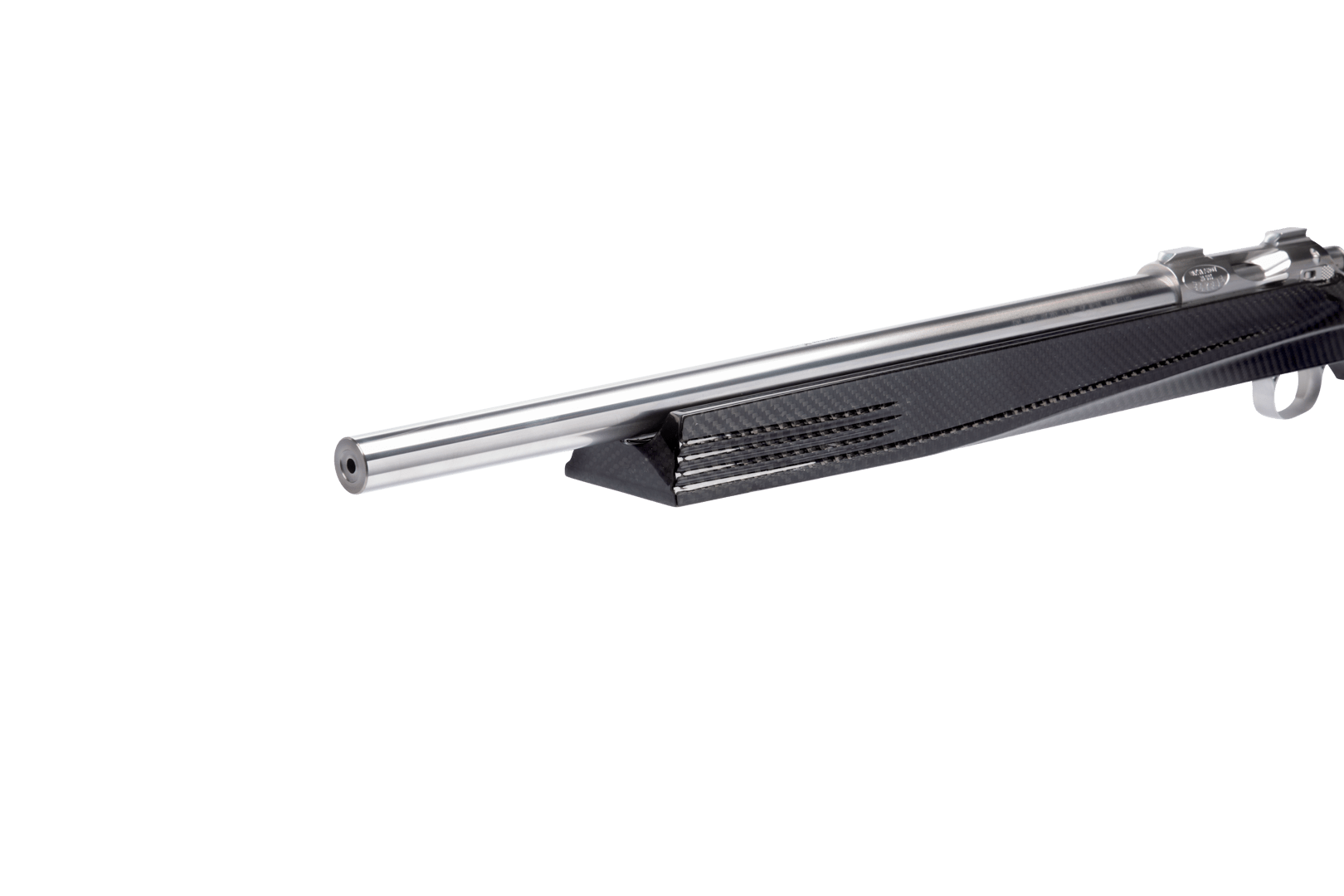

We wrap thin barrel cores in various diameters and weights with carbon rovings directly onto the barrel steel. The advantage of this method is that a wrapped carbon barrel maintains the weight of a slim barrel, the shooting performance of an average barrel and the external dimensions of a strong barrel.