Precision through perfection – our motto probably best describes the development process of the “Elypse”. Our competitive rifle is characterized by an uncompromising technical concept, coupled with state-of-the-art manufacturing processes and high-quality materials.

The special shape of the system immediately catches the eye of the attentive observer: an elyptical cross-section counteracts the mainly vertical running vibrations and at the same time saves weight in less stressed areas. The tapered shape from front to rear ensures high stability at the root and weight savings at the rear.

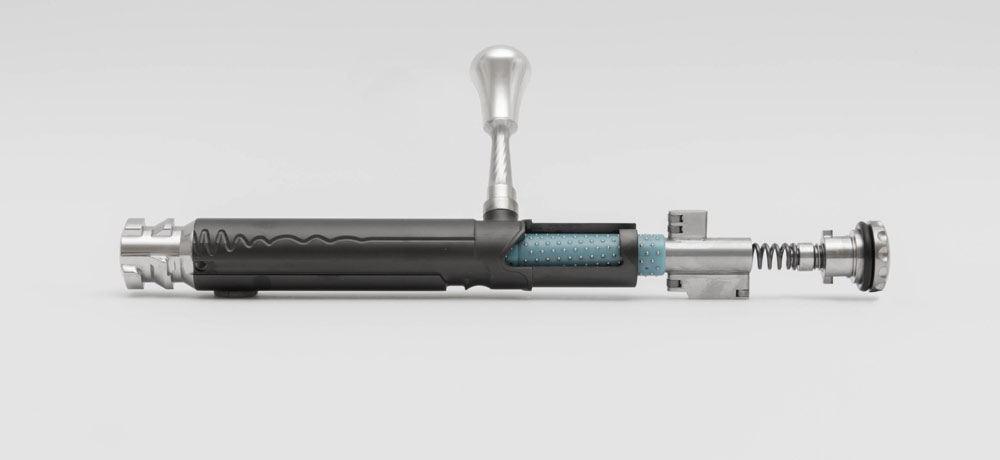

The clasp of the “Elypse” is equipped with a ground-in 6-lug locking mechanism and is made out of 2 parts. The bolt head is made of tempered stainless steel to ensure maximum stability, while the Light Varmint corpus is made of lightweight titanium.

A ball cage ensures the most consistent ignition energy on the market and is used for linear guidance of the firing pin. In addition, roller bearings are fitted to the clamping cam and at point of contact to ensure easy opening. The firing pin’s spring force can be adjusted infinetly by means of a screw at the rear end of the bolt. To prevent any tension on the firing pin and to ensure exact concentricity of the firing pin, the firing pin is split.

In order to achieve a perfect compromise between vibration damping and weight, carbon fiber mats are laminated onto a balsa wood core in a specially manufactured mold for the stock. Both the negative shape of the system and the pull-off bracket are created directly during lamination so that the fiber structure of the carbon is not unnecessarily interrupted by subsequent milling work.